Tank lifters that optimize efficiency in your processes

What are the benefits of bin hoists?

At Roser Group, we design column lifters that optimize vertical transport in the food industry, ensuring an efficient and safe workflow while making workers' tasks easier.

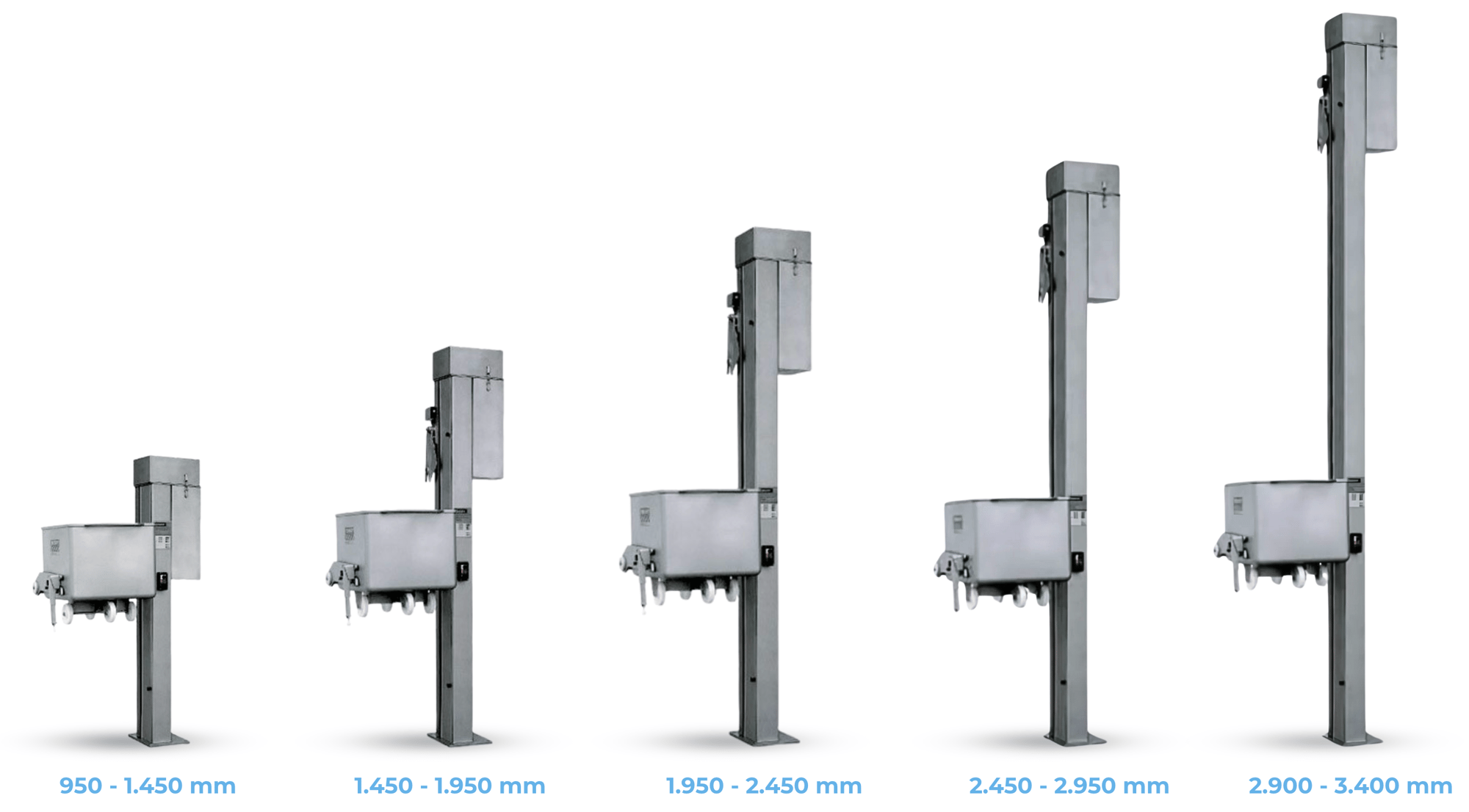

Discharge height from 950 a 3.400 mm

Our range of lifters adapts to any requirement in the food industry, with options ranging from 950 to 3,400 mm in height. We design custom solutions to optimize production processes, ensuring efficiency and safety in load handling.

Left or right position

We offer lifters with right-hand or left-hand configuration, allowing integration into any production line without the need for major modifications. This versatility enhances ergonomics and operational efficiency.

Frontal o lateral loading

Our lifters are designed to fit different workflows, with options for front or side loading of the tank. This flexibility allows for optimizing available space and improving the internal logistics of the plant.

Buggy lift and dumper

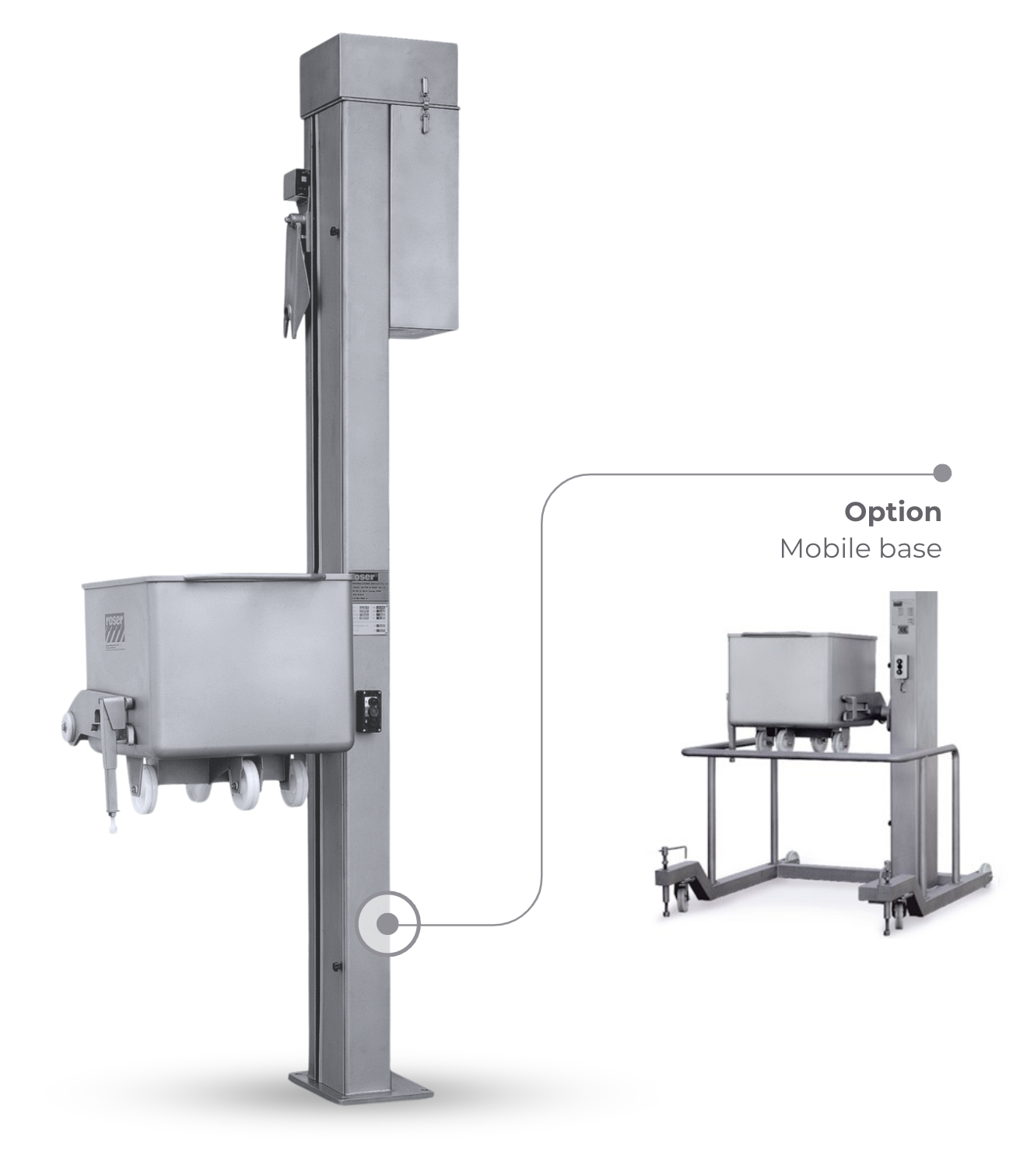

Roser's buggy lift and duumpers are designed to provide reliable and safe operation, optimizing the handling of tanks up to 300 liters.

Their robust construction and ability to adapt to different types of bins allow for quick loading and unloading, significantly reducing manual effort. Equipped with advanced technology, these lifters ensure efficient, smooth, and low-maintenance operation thanks to their screw conveyor system.

Additionally, the high-quality materials used ensure excellent resistance to corrosion, extending their lifespan.

Available in various discharge heights, they offer a versatile solution to improve productivity and operational safety in any industrial environment.

*Optional mobile base for lifters, compatible with all Roser models.

| Model | Discharge height |

| RC00009179 (left) / RC00009156 (right) | From 950 to 1.450 mm |

| RC00009303 (left) / RC00009251 (right) | From 1.450 to 1.950 mm |

| RC00009307 (left) / RC00009159 (right) | From 1.950 to 2.450 mm |

| RC00009637 (left) / RC00009479 (right) | From 2.450 to 2.950 mm |

| RC00002188 (left) / RC00002189 (right) | From 2.900 to 3.400 mm |

Lifters adaptable to all types of bins

Roser Group's buggy lift and dumper adapts to a wide variety of bins, ensuring versatility and efficiency in production plants. They integrate perfectly into different production processes and with various types of tanks, facilitating compliance with DIN 9797 standards for standard 200 and 300-liter bins.

We work with standard bins, Jumbox bins, and other models, offering lifters fully tailored to your needs and specific measurements. Additionally, they allow the incorporation of a funnel in the bin fork to improve product discharge.

Mobile tipping device or dumper for bins

The mobile tipping device for standard 200 and 300-liter bins is designed for efficient and safe handling. Made of AISI 304 stainless steel, it offers a maximum load capacity of 350 kg and a discharge height of 1,100 mm.

Its operation is based on a pneumatic system with a 160 mm diameter lifting cylinder and a working pressure of 6.3 bar (7 kg/cm²). To ensure safe use, it includes a hopper that prevents product spills and a reinforced structure. Additionally, its integrated wheels make transportation easier, providing a versatile and practical solution for tank management.

Robust and durable equipment

Hygienic design, easy to clean and maintain

Technical support

service

Mobile pneumatic vat dumper

The mobile pneumatic vat dumper for containers and bins has a discharge height of 1,100 mm and a maximum load capacity of 500 kg, including the container. Its design is tailored to the customer's needs, according to the characteristics and dimensions of the tank.

Built with AISI 304 stainless steel, this dumper includes a hopper to prevent product spills and operates with a working pressure of 6.3 bar, providing a robust and efficient solution for load handling.

Robust and durable equipment

Hygienic design, easy to clean and maintain

Technical support

service

Mobile hydraulic container dumper

The mobile hydraulic container dumper, built with AISI 304 stainless steel and mounted on wheels, is designed to handle different types of tanks, such as brining, jumbox, or maceration tanks. It operates with a hydraulic cylinder powered by a hydraulic unit with a three-phase electric motor.

This dumper offers a maximum load capacity of 1,000 kg (including the container) and a tipping height of 1,100 mm. With a power of 1.5 kW, its design is customized to meet the specific needs of the customer.

Robust and durable equipment

Hygienic design, easy to clean and maintain

Technical support

service

Mobile hydraulic container dumper

· Dump system: electrovalve G-3/8”.

· Reinforced structure with side protections included.

· Hopper for prevent output drops.

· Integrated control box and switch board.

· The dimensions may change according to the dimensions of the container to be loaded.

Column lifters for bins in action

Discover our column lifters for bins, designed to meet the highest demands of the food industry. Top-quality solutions to optimize handling and ensure safety in processes.

Why trust Roser Group?

With over 60 years of experience, we are recognized as a global leader in the design and manufacturing of equipment and facilities for the food industry, especially the meat sector. We specialize in hygiene machines, cutting rooms, and food processing lines.

In our R&D department, we develop environmentally responsible designs while considering the health of our workers. We replace polluting materials with sustainable alternatives like LED lighting. Our machines and equipment are designed to be ergonomic and practical for technicians, while also improving energy and water efficiency.

Benefit from our technical service

Our great team of professionals will provide you with a complete and long-lasting technical service with spare parts for machines with more than 25 years.

In order to expand our services, we also have a large number of collaborating companies in different countries around the world to monitor and support our clients.