Maximum hygiene for industrial footwear with walk through automatic boot washers

Effective automatic and semi-automatic hygiene systems

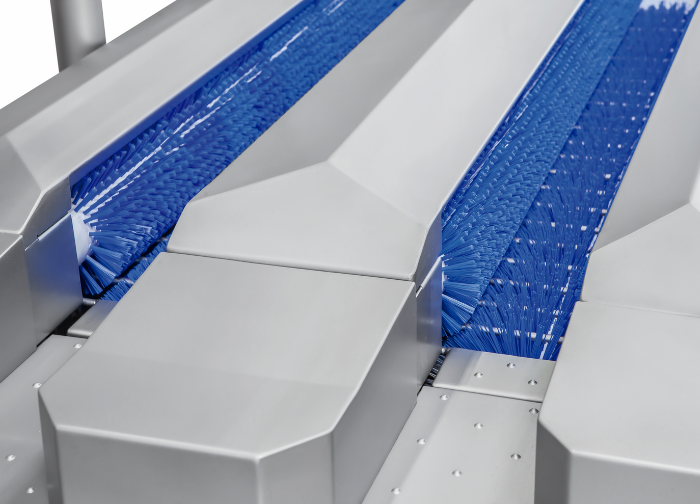

LB boot washer walk through system

The best solution to maintain hygiene with high worker traffic

Keep personnel footwear clean easily and without waiting times with the LB 1200 boot washer walk through system.

Specially designed for the food and meat industries, this continuous washing system instantly removes solid residues from the soles and shafts of boots, thanks to its horizontal rotating brushes for the soles and inclined brushes for the shaft while the worker walks through the boot washer.

The process starts automatically when entering the equipment, using water and detergent to ensure maximum hygiene and comply with all food safety regulations.

Robust and durable equipment

100% Automatic

Cleans boot shafts and soles

LB boot washer walk through system

· Activated by IP69K photocells.

· Food Defense protection in stainless steel for the soap container (not included).

· Boot cleaning through automatic rotation of the brushes with water and detergent supply. End of process detected by photocell at the equipment's exit.

· Solenoid valve to control the water supply and proportional water-detergent mixer. Water pressure according to the network (detergent container not included).

· Operates in both directions.

· All models available with 3 brush lengths: S 800, M 1,200, L 1,600 mm.

· Electrical supply: 400V – 3Ph – 50Hz.

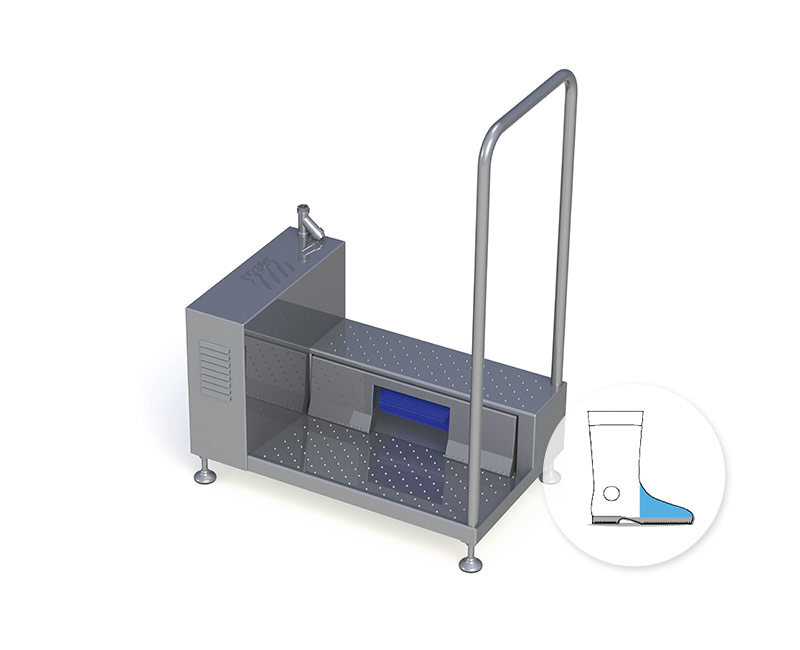

LZ boot washer walk through system

With the LZ boot washer walk through system you can ensure proper washing and disinfection of personnel footwear before entering the factory or a high-risk area.

The washing of low boots and soles is carried out automatically by photocell activation of the rotating brushes.

The equipment operates in both directions and is ideal for preventing staff wait times.

Robust and durable equipment

100% Automatic

Low boot and sole washing

LZ boot washer walk through system

· Washing of low boots and soles through automatic rotation of the brushes with fluid supply.

· Brush activation via photocell.

· Venturi-type detergent dispenser (container not included).

· Operates in both directions.

· All models available with 3 brush lengths: S 800, M 1,200, L 1,600 mm.

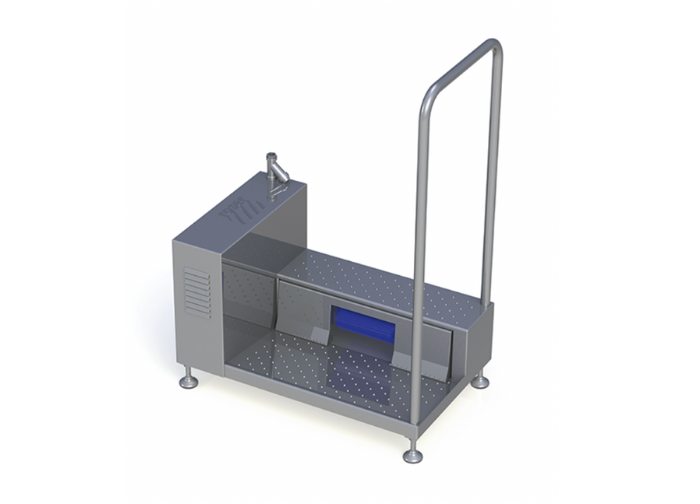

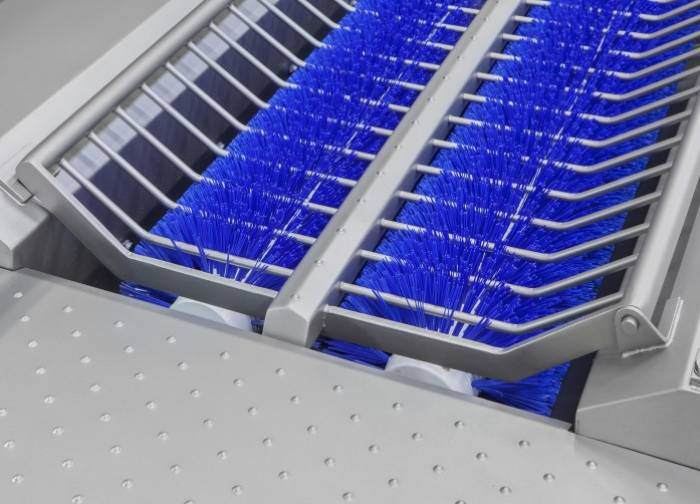

LS sole washer walk through system

The LS sole washer walk through system is designed to ensure effective disinfection of footwear soles in the food industry.

Thanks to its rotating brush system with water supply and detergent dosing, this equipment ensures deep cleaning with every step. Its automatic activation via IP69K photocells allows for efficient, contactless use.

It complies with the strictest safety and hygiene regulations, being compact, durable, and easy to install—perfect for any area of the food or meat industry.

Robust and durable equipment

100% Automatic

Sole washing

LS sole washer walk through system

· Stainless steel Food Defense protection for the soap container (not included).

· Activated by IP69K photocells.

· Sole washing through automatic rotation of the brushes with water supply and detergent dosing. Process ends via timer. The equipment operates in both directions.

· Features a solenoid valve to control water supply and a proportional water-detergent mixer. Water pressure according to the network (detergent container not included).

· Modular brushes are easily accessible and removable for cleaning and maintenance.

· Independent drive for each brush axis.

· Available with brush lengths S 800, M 1,200, and L 1,600 mm.

· Electrical supply: 400V – 3Ph – 50Hz.

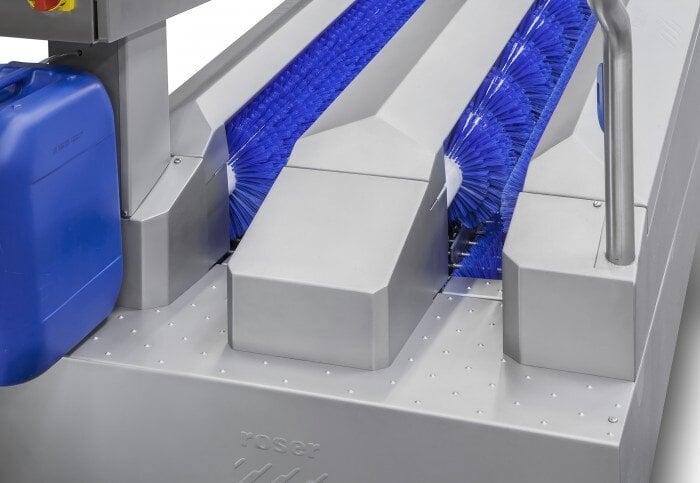

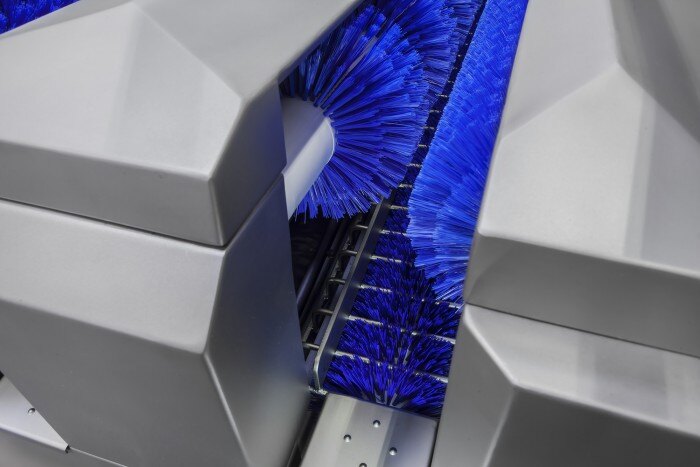

3-brush automatic boot washer

Prevent cross-contamination in the food industry with the 3-brush automatic boot washer. It simultaneously cleans the sides and soles, ensuring effective cleaning of personnel footwear.

Ensure that contaminants are not transferred from one room to another with our industrial automatic boot washer.

It features 2 vertical rotating brushes and 1 rotating sole brush with automatic soap supply (soap container not included).

Robust and durable equipment

100% Automatic

Cleans boot shafts and soles

3-brush automatic boot washer

· Automatic operation via IP69K photocell.

· Activated by IP69K photocells.

· Side and sole cleaning through automatic rotation of the brushes with water supply and detergent dosing. Process ends when the boot is removed.

· Solenoid valve to control water supply and proportional water-detergent mixer (detergent container not included).

· Water pressure according to the network.

· Electrical supply: 400V – 3Ph – 50Hz.

Semi-automatic boot washer with manual brush

Semi-automatic boot washer with manual brush, designed to prevent the transfer of contaminants between areas via workers' footwear.

This system offers semi-automatic sole cleaning with one rotating brush and two fixed brushes, ensuring a thorough cleaning.

Additionally, it has an automatic detergent dispenser and a manual brush activated by a foot pedal, ideal for effectively cleaning the sides of boots.

Robust and durable equipment

Automatic rotation with manual brush

Cleans boot shafts and soles

Semi-automatic boot washer with manual brush

· Sole cleaning through automatic rotation of the bottom brush with water supply and detergent dosing, activated by contact on the handle.

· Upper and side cleaning via manual brush with a valve activated by pressing a button, allowing water to flow through the brush.

· Proportional water-detergent mixer, water pressure according to the network (detergent container not included).

· Electrical supply: 400V – 3Ph – 50Hz.

Manual boot washer

Ensure the cleaning and disinfection of workers' footwear with Roser Group's manual boot washer, a simple-to-install unit that requires no electrical consumption.

It only needs to be connected to the water supply, and the washing system is activated by stepping on the pedal, directing the water flow to the special boot brush.

The manual boot washer helps maintain hygiene and safety protocols in any industry, effectively and easily preventing the spread of contaminants between production areas.

Robust and durable equipment

Manual system with pedal activation

Cleans boot shafts and soles

Manual boot washer

· Manual cleaning of boot soles and sides using a manual brush.

· Water flow is activated by pressing the pedal, allowing water to pass through the brush.

Robust and durable equipment

Electric switch activation

Toe-cap and footwear cleaning

Automatic toe-cap washer

· Activated by an electric foot switch.

· Equipped with a solenoid valve to control water supply and a proportional detergent mixer. Water pressure according to the network (detergent container not included).

· Water is used as a once-through system with filtration.

· One modular brush Ø150x200 mm.

· Wash module adaptable to sole washers, shoe washers, and boot washers.

· Electrical supply: 400V – 3Ph – 50Hz.

Automatic industrial boot washers in action

See our boot washers designed to meet the most demanding needs of the food industry. Superior quality solutions to ensure the safety and hygiene of your processes.

Why trust Roser Group?

With over 60 years of experience, we are recognized as a global leader in the design and manufacturing of equipment and facilities for the food industry, especially the meat sector. We specialize in hygiene machines, cutting rooms, and food processing lines.

In our R&D department, we develop environmentally responsible designs while considering the health of our workers. We replace polluting materials with sustainable alternatives like LED lighting. Our machines and equipment are designed to be ergonomic and practical for technicians, while also improving energy and water efficiency.

Success story

Nestlé Chile, a leading multinational in the food sector, has trusted Roser Group for over 30 years to optimize its industrial hygiene processes. T

hroughout this strong partnership, Roser Group has implemented various technological solutions, including three Duomans Plus systems, ensuring the highest standards of safety and hygiene in their facilities.

Benefit from our technical service

Our great team of professionals will provide you with a complete and long-lasting technical service with spare parts for machines with more than 25 years.

In order to expand our services, we also have a large number of collaborating companies in different countries around the world to monitor and support our clients.