High performance sausage peeling

Traditionally, sausage peeling production, has been carried out by skinning the product manually and one by one, making this a slow and tedious process.

Integrating an automatic sausage peeler machine in your peeling process not only substantially improves production performance, but also gives you a wide range of advantages such as avoiding product contamination or reducing the ecological footprint thanks to its low electricity and steam consumption.

On the other hand, a wide range of diameters is offered to peel different sizes of sausages, including cocktail, all in the same space.

Therefore, from Roser Group, we are committed to an easy peel sausage peeling process, where you will be more efficient and respectful with the environment.

Pros of Sausage peeling machine

Our proposal in Roser Group improves and solves existing problems in other brands

Unmarked sausages

The automatic sausage peeling process guarantees an optimal result without leaving any type of mark on the final product.

Energy efficiency

With our sausage detection photocell, the machine automatically enters ECO mode when the sausage peeling process stops, thus improving energy efficiency.

Low steam consumption

The PTF Super Plus sausage peeler machine significantly reduces steam in the room offering a cleaner workspace compared to other brands.

Variety of diameters

With a high capacity output of 300m/min and a diameter range between 15-35 mm, the PTF Super Plus can handle a wide variety of sausage sizes, including the cocktail type.

Anti-scald system

The sausage peeler machine incorporates an anti-burn system to prevent operators from experiencing discomfort during product handling.

Hygienic design

The design of the PTF Super Plus makes its cleaning and day to day maintenance simple, comfortable and very easy, since it is completely tool-free.

2 models available

From Roser Group we offer you two models of sausage casing peeler: the PTF Super Plus and the PTF Compact

Sausage Peeler PTF Super Plus (CATO)

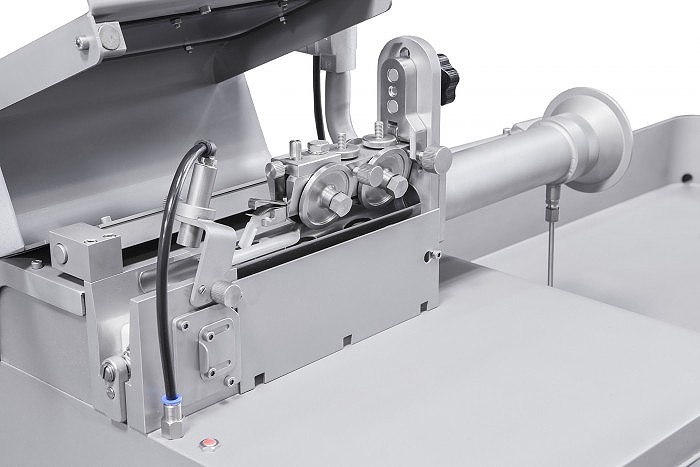

Roser Group presents the new automatic sausage peeler machine PTF Super Plus (CATO). This ready to use machine model fully integrates the entire sausage peeling production process.

Waste casing is collected in the incorporated tank of the machine.

Completely built in high quality stainless steel and according to CE regulations, it presents a new cutting system with an easily adjustable blade.

It also offers a cold air curtain protection system to avoid burns in the operators and automatic disconnection or ECO mode of the peeler when not in use to improve energy efficiency.

* This model includes the waste deposit module.

Lower steam consumption

The PTF Super Plus has a low steam consumption of 16kg / h compared to the average of 50-78kg / h. Improving the quality of the air in the workspace and lowering the risk of bacteria due to humidity and heat.

Less noise pollution

Thanks to our design, the PTF Super Plus design emits less noise in operation compared with other existent solutions in the market.

Easy cleaning process

The cleaning process of the PTF Super Plus is designed to be easy and convenient since it is completely tool-free and easy to perform by a non-skilled operator.

PTF Super Plus Features

· Productivity: up to 300m/min

· No crop marks on the product

· Wide range of product diameter and length to be processed

· Peeling speed control

· Designed and built under European regulations

· System equipped with a high-performance vacuum generator

· Careful traction system

· Control and regulation of steam supply

· Automatic steam shut-off system or ECO mode

· Anti-burn air curtain

· Easy blade adjustment system that allows the manipulation of the carriage without losing the configuration

· Minimum regulation and adjustment to blade change

· Hygienic and easy-to-clean overall design

· Top brand components

· High build quality: 304 and 316L stainless steel

Sausage Peeler PTF Compact (CATO)

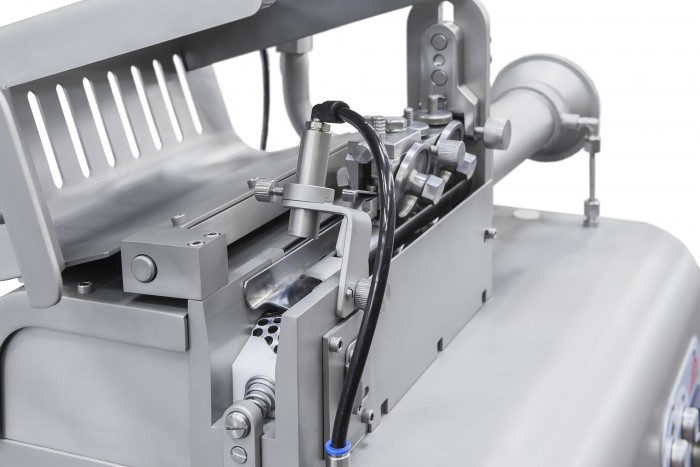

Roser Group also presents the brand new PTF Compact (CATO) sausage peeler.

This model is the compact version of the PTF Super Plus, ideal for production plants that have a centralized vacuum system.

High speed sausage peeling, including cocktail sausages, without leaving any marks on them.

Entirely built in stainless steel and according to CE regulations, it presents an exclusive blade adjustment system that allows the handling of the cutting head without losing its adjustment.

It also offers a cold air curtain protection system to avoid steam related incidents when peeling, and automatic disconnection of the peeler when not in use to improve energy efficiency.

* Casing waste module not included.

Central vacuum connection

The PTF Compact is a smaller and more manageable model ideal to be installed in factories with a centralized vacuum system.

Lower steam consumption

The steam consumption of the PTF Super Plus is 16kg / h compared to the average of 50-78kg / h. Improving the quality of the workspace for a cleaner one.

Less noise pollution

The design of the PTF Super Plus emits less noise in operation.

Easy cleaning process

The cleaning process of the PTF Compact is designed to be easy and convenient since it is completely tool-free and easy to perform by a non-skilled operator.

PTF Compact Features

· Productivity: up to 300m/min

· No crop marks on the product

· Wide range of product diameter and length to be processed

· Designed and built under European regulations

· System equipped with a high-performance vacuum generator

· Careful traction system

· Control and regulation of steam supply

· Automatic steam shut-off system or ECO mode

· Anti-burn air curtain

· Blade adjustment system that allows the manipulation of the carriage without losing the configuration

· Minimum regulation and adjustment to blade change

· Hygienic and easy-to-clean overall design

· Top brand components

· High build quality: 304 and 316L stainless steel

PTF models in action

The design of the models of the automatic sausage peeler machine is thought to improve the efficiency and the handling in the peeling of sausages to offer a quality result, in addition to having an easy maintenance and a comfortable and safe design for the operators.

Why Roser Group?

More than 60 years of experience guarantee us as a world leader in the design and manufacture of equipment and facilities for the food industry and especially the meat industry. Hygiene machines, cutting rooms and food processing lines.

Within the R&D department we develop our designs that are responsible for the environment and taking into account the health of our workers. We substitute polluting materials for sustainable materials such as LED lighting. Our machines and equipment are designed to be ergonomic and practical for technicians, and we also manage to improve efficiency in energy and water consumption.

Case Study Greisinger (Austria)

Based in Münzbach, the Greisinger company presents itself as one of the largest and most modern meat processing companies in Austria.

With the aim of improving their production methods, Greisinger decided to acquire the PTF Super Plus automatic sausage peeler machine, which allowed them to improve their service productivity, be more agile in processes and reduce air vapor levels, thus improving the ecological footprint.

Benefit from our technical service

Our great team of professionals will provide you with a complete and long-lasting technical service with spare parts for machines with more than 25 years.

In order to expand our services, we also have a large number of collaborating companies in different countries around the world to monitor and support our clients. Visit our support page here